Exlabesa Architecture ensures top performance for its aluminium windows and doors thanks to an advanced in-house Testing Lab

- -Exlabesa Architecture operates an in-house advanced Testing Lab to test its window and door systems, ensuring that their products exceed UK industry standards such as BS 6375-1.

- -Weather tests are designed to evaluate how materials and products resist adverse weather conditions, such as rain or wind. After in-house testing, the products are certified by independent laboratories.

With an advanced in-house testing lab, Exlabesa is able to thoroughly test its products during the development phase and ensure its compliance with UK’s industry standards such as BS 6375-1, which covers different aspects of performance.

Weather testing is essential to ensure that aluminium windows and doors maintain their structural integrity, airtightness and aesthetic appearance over time, even in adverse weather conditions such as those found in the UK. This guarantees that the products meet the quality and safety standards required by Building Regulations and other standards.

These tests are especially important to Exlabesa Architecture, as our systems are exposed to different atmospheric elements throughout their long service life. The differential characteristics of aluminium (strength, durability, low maintenance, safety for humans and the environment) allow us to design and fabricate systems that will remain practically intact throughout the years.

BS 6375-1. Weathertightness

The BS 6375-1 standard provides guidance on the required performance levels for air permeability, water tightness, and wind pressure specific to the UK market. Even though a product’s performance should match the conditions of its intended location, it’s usually professionals such as architects or building designers who specify this performance level for windows or doors.

This standard contemplates three types of weather tests that are reflected in data scales that will appear in the technical data sheets of each product:

- -Air permeability: measures the amount of air that can pass through the window or door under different pressure levels. It is classified from Class 1 (lowest) to Class 4 (highest performance).

- -Water tightness: evaluates the ability of the window or door to prevent water penetration under different pressure levels. Classified from Class 1A to 9A, with an additional class E for extreme conditions.

- -Wind resistance: assesses the structural performance under wind load. Classes range from 1 to 5, with higher numbers indicating greater resistance.

These standards ensure that aluminium windows and doors are rigorously tested to help manufacturers, builders, and consumers select and specify products that meet the necessary performance criteria for use in the UK.

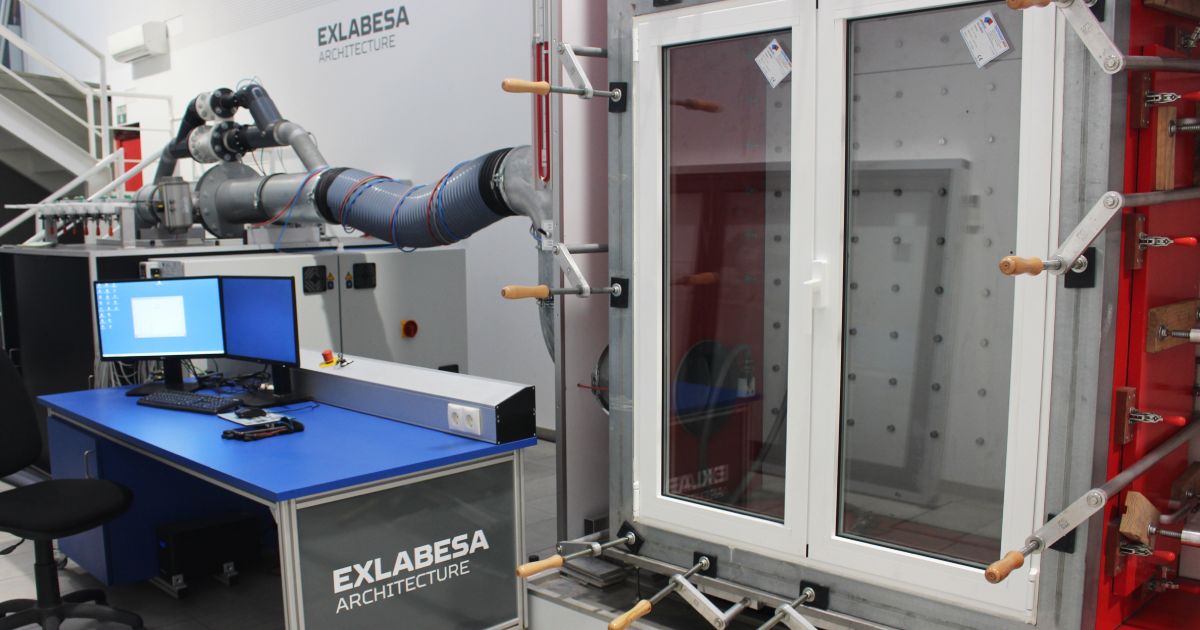

Exlabesa Architecture’s advanced testing facilities

Exlabesa Architecture operates its own laboratory equipped with a series of state-of-the-art test benches designed to test products during their development phase. In this way, Exlabesa continuously improves the efficiency, performance and safety of its systems, beyond regulatory compliance, guaranteeing the best results.

After design, development and testing to the highest standards in our in-house facilities, all our products are sent to independent, external testing laboratories for official certification to British Standards.

You can check all Exlabesa’s system’s performance data listed on their technical sheets, as well as technical manuals (available through our digital platform Exlabesa 360). If you have special requirements for your project and need assistance choosing the most adequate ones, do not hesitate to contact us.